Louis De Poortere has acquired worldwide reputation as manufacturer of the most beautiful woven velvets for carpets and fabrics. The group has the largest vertically integrated Wilton production of the industry with its :

- Own Dying

- Own Weaving

- Own Spinning

- Own Confection

- Own Logistical Platform

- Outgoing Finished Goods

- Strong Procedures For Incoming Raw Materials

What does Louis De Poortere stand for ?

- Heritage is based on talents of Flemish weavers !

- A long-standing tradition established over 100 years ago

- A desire for progress

- Quality and creativity

- Innovation and technology

Benefits of Louis De Poortere carpets

Specialists in producing authentic woven Wilton carpets use the finest 100% pure new wool yarns for the ultimate luxury woven to exacting manufacturing standards using the finest quality raw material using 2-ply and 3-ply yarns for extra resilience focussed on sustainability with products developed to be 100% biodegradable

Why buy a carpet ?

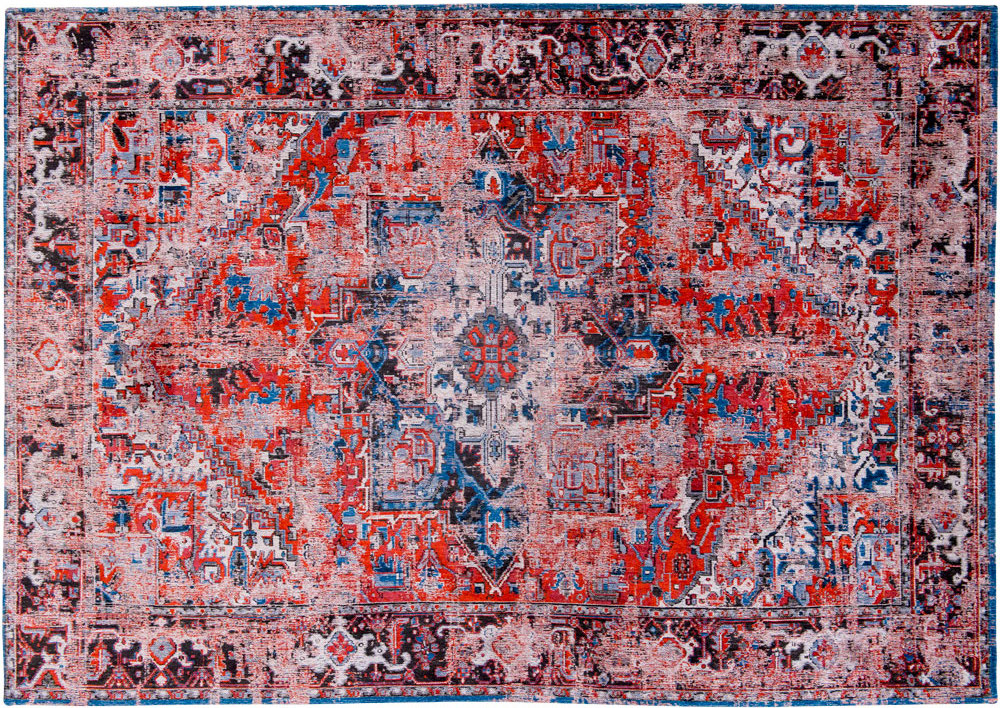

There is nothing quite like woven carpets to add comfort, warmth and character to a room.

A carpet will transform an interior in a way that no other single item of furniture can, yet will often cost less and last longer.

Noise Reduction

A carpet cushions the impact of the noise, aiding relaxation and improving ambiance

Dust Trapping

Carpeted rooms have better air quality than rooms with hard flooring. It traps dust in the pile until removed by vacuuming. Wool carpets also show air quality improvement through lower VOC’s and improved humidity control

Energy saving

Carpets do not only create the feeling of warmth, they actually help retain heat in a room by acting like a thermal insulator

Environmental impact

Why buy a Woven carpet ?

When buying a carpet it is important to buy a product equal to the task, avoiding early replacement and ensuring value for money.

Woven carpets have 3 distinct advantages:

Appearance retention

Dynamic stability

Precision of texture

The interlocking warp threads (lengthwise) and weft threads (crosswise) are produced in such a way

that the tufts of carpet yarn are secured between them row by row.

The backing and surface are created together during weaving making the carpet dimensionally stable.

The manufacturing process produces a very precise texture which is difficult to emulate in tufted carpets

WILTON WEAVING

- Plain or single-frame Wilton comes from the traditional 'Warp and Weft' weaving process.

- It is generally considered the most 'authentic' and 'prestigious' of all weaving processes.

- A traditional Wilton weave carpet is one in which the pile threads run continuously into the carpet and are raised above the surface of the integral backing by means of wires or hooks.

- As the backing is being woven, pile yarns are introduced lengthways, (that is, from the warp direction) and looped over wires inserted across (weft direction) the weaving machine.

- A patterned effect in a combination of cut and loop rows may be created and enhanced by using stippled or multi-coloured yarn combination.

Woven using pure new wool and the benefits

Excellent resilience – it recovers well from shoe and furniture pressure

Resists soiling and cleans easily

Naturally flame retardant

Excellent appearance retention – natural ‘springiness’

Improves indoor air quality – wool absorbs and neutralises air pollutants

Good colour dye absorption – carpets have rich, clear colouration

Luxurious appearance – and good looks that last

Good moisture buffering and electrostatic properties

Wool

Change to a safer & healthier environment

WOOL IS A NATURAL FIBRE

FOR THE WORLD WE LIVE IN TODAY

WITH A TRUE ‘GREEN’ LINEAGE

Wool is natural

Renewable

Sustainable

Biodegradable

Low carbon impact

Energy efficient

Wool is safe

Flame resistant

UV protection

Static electricity reduction

High thermal resistance

Wool is healthy

Breathable

Humidity Control

Low allergy

Toxic chemical absorption

Sound reduction